WHAT IS

REFURBISHMENT?

The life of a set of aluminium formwork is ideally 200 repetitions. After desired repetitions are completed based on project completion, the used formwork needs to be redesigned and refurbished as per new building design requirements. This ensures maximized cost effectiveness for the client, by minimizing or eliminating the need to buy new sets of aluminium formwork. At Cosmos, we have designed a special process of refurbishment to achieve this.

WHY CHOOSE

REFURBISHMENT?

Refurbishment of aluminium formwork by Reformer brings with it many advantages, which makes it a great choice.

LOWER COST

Significantly reducing the cost of formwork per sq. m.

MORE REPETITIONS

One set achieves 100 repetition

EXCELLENT QUALITY

Reused material offers same quality as new material

REFURBISHMENT

A 13-STAGE

PROCESS BY REFORMER

- Stage 1

- Stage 2

- Stage 3

- Stage 4

- Stage 5

- Stage 6

- Stage 7

- Stage 8

- Stage 9

- Stage 10

- Stage 11

- Stage 12

- Stage 13

DRAWING

It involves looking at the old drawing and creating a new shell drawing. Then, a new modulation drawing is made that includes old & new material.

INSPECTION

Old material is sorted to be used for a new project. A bifurcation of damaged and well-conditioned panels is done, followed by checking for refurbishment.

CHIPPING

A device called chipper is used to remove concrete lumps from shortlisted panels and sections.

DIPPING

The chipped panels are dipped in a chemical tank to 100% remove the concrete sticking on the sides of the panels.

CLEANING

Using a powerful jet spray, the panel is washed and cleaned with water.

LEVELLING

Using a hydraulic press machine, the panel is straightened and undulations, if any, are removed.

CUTTING & WELDING

Using a standard welding machine, the damaged or cut part of the panel is welded.

BUFFING

The surface of the panel is now prepared to receive a lacquer coating, with the help of a buffing machine.

COATING

To achieve a smooth finish and easy removal of the panel, a lacquer coating is done using an air compressor, air pipe and paint gun.

BARCODING

Before handing over to the client, barcodes are stuck to the final product. The barcode carries the project code and site code.

HANDOVER & MOCKUP

Material is handed over room wise by barcode scanning. Based on hole matching, necessary modifications are done with provision of bracket holes.

CODING

A panel carrying the project name, element name, building name with site location, along with barcodes and QR scanners is put on the panel.

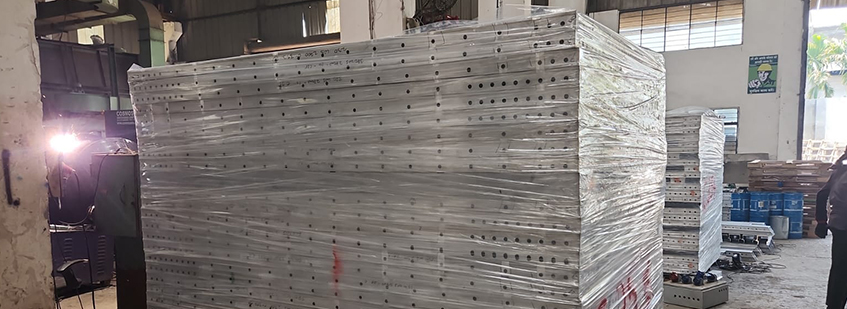

PACKAGING & TRANSPORTING

Based on concrete pour, packing list is prepared and the delivery is done at client site.

Our Esteemed Clients

India’s accelerated push for development and infrastructure has given rise to demand for a lot of machinery and solutions to make it happen. As a result, Cosmos has become a reliable choice for many leading names from real estate and other infrastructure development sector. From Pune to across India, reputed names have been choosing Cosmos repeatedly for their key projects to ensure hassle-free on-site project work.

about Reform

GET IN TOUCH

Establish seamless communication with us. Whether you have inquiries about our offerings, require assistance, or seek collaboration opportunities, we invite you to reach out. Our team is committed to delivering prompt and professional support tailored to your needs.